UPDATE 2017: I canceled my order for the Glowforge as life happens and I couldn’t afford to let them earn interest on my money anymore. I just had to get my money back for life reasons. I do still recommend you get one if you can. I’ve seen them in use in person at Charlotte Latin FabLab and it is really awesome!

Original article below:

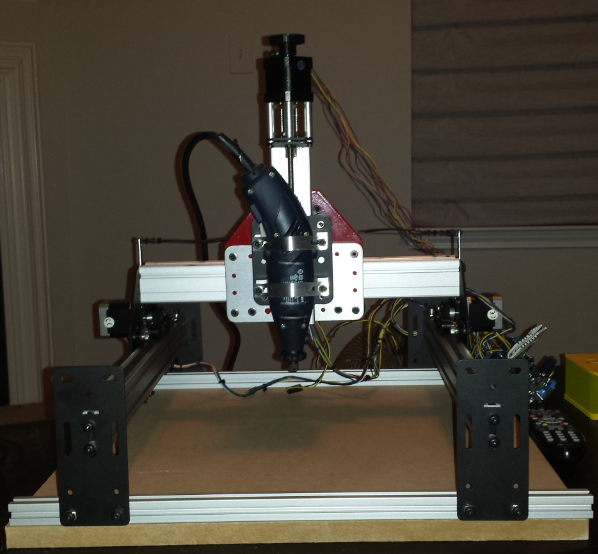

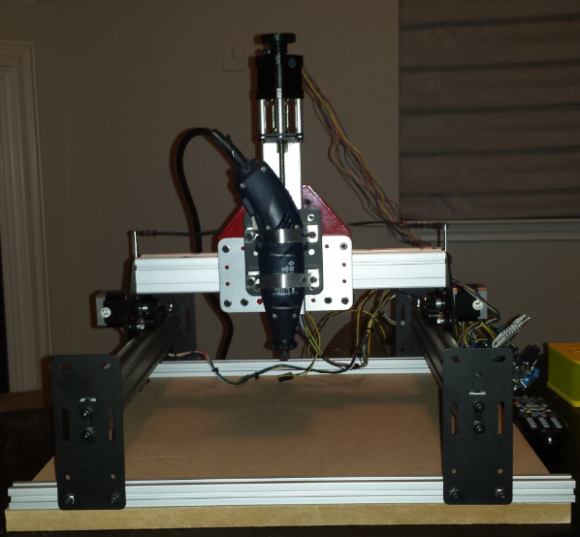

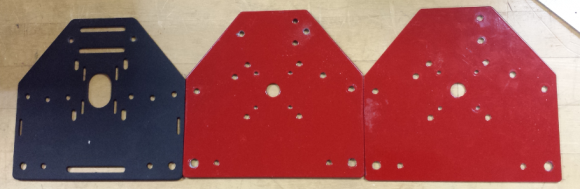

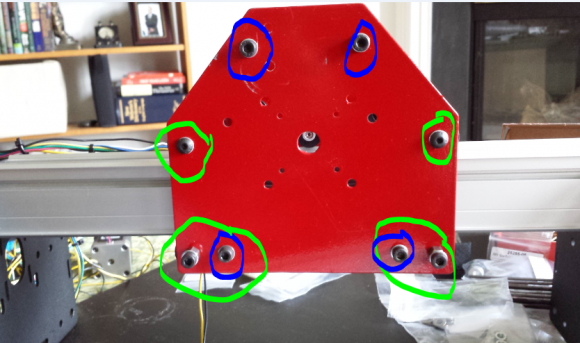

So for the last 7 years or so, Jess and I have considered purchasing a laser cutter. My personal goal is to have my own FabLab. I’m partially there with Jess’s KNK Zing vinyl cutter and my Shapeoko/Xcarve CNC machine. The two main missing components are a 3D printer and a laser cutter. Being a FabAcademy alum and running a FabLab at work, I am intimately aware that lasers are the most used (and arguably useful) machine. They are definitely the most fun to play with. They are also the easiest to make money with (It’s always easiest for me to justify big purchases with the expression “hobbies that pay”). For the past several decades, laser cutters or laser engravers have been used in trophy shops and all sorts of companies. You can use a laser cutter to make products to sell on Etsy (as many people do), make the most amazing personalized birthday and holiday gifts, prototypes of ideas you have, or just make cool stuff for yourself.

I recently saw a new laser cutter on the market and I held back for a while before making the decision to buy it. That may have been a mistake. The GlowForge is shaping up to be a great machine. I’ve followed it since September, when they were offering 50% discounts on all models. At the time of this article, they have raised the price to 40% off retail price. And, if you use this referral code, both you and I will get $100 off our orders! (In full discretion, I have had no contact with Glowforge, nor have I actually use the machine myself yet. I’m just really stoked with this machine and its potential. I do have a PhD in Computer/Electrical engineering with Computer Science background and I run an official node of the FabLab network that was started at MIT, so hopefully I’m not off base here… )

There are lots of cheap ( <$15k ) 40-watt laser cutters on the market such as some cheap Chinese ones from Alibaba, or Full Spectrum. So why go in on a Glowforge? Well quite simply, it is the best designed laser cutter for FabLab/Makerspace/Hackerspace use. Unlike others in the price range, you don’t need a 5 gallon bucket of distilled water and a fish pump to cool the laser tube (yes that’s a real thing some other models at these prices require and it is ridiculous). It breaks the paradigm of how users interact with a laser cutter. It is following some of the latest research on user interface and user experience in the field of computer science. Honestly, those are project I wish I could implement myself but didn’t have the time. It brings together lots of great solutions from these projects and crams it all into a single package.

Paradigm shift #1: Unlike traditional laser cutters, where you print to the machine like a printer on a network or connected to your computer, Glowforge can be printed from practically any location in the world. This is because the software is cloud-based. I used to be wary of this kinds of thing, but since Glowforge also promises to make a version of the software open source, you can implement it yourself if you want.

Paradigm shift #2: Glowforge allows you to easily position your designs on your material using a live camera view of the material. This is a godsend for those who are familiar with the waste of laser cutters. To be able to make sure a design will fit on a scrap piece of material, you have to do some measurements, hold your tongue just write when pushing the cut button, and hope you remembered to reset the origin (0,0 point) on the laser before cutting. Sometimes this can be very hard depending on what was originally cut out of the scrap you are using, you might have a weird shaped area and it can be very hard to find out if you can use it to cut a new part. There are some ideas being researched to handle this kind of situation and other tools you can purchase that are very expensive, but Glowforge has it built in. Being able to literally move my design on top of a video camera image of the material allows me to use as much material as possible without the risk of mis-cutting and having to toss that piece of material and grab a new one.

Another great feature is to simply draw on the material you want with a pen. The cameras will read your design, vectorize it, then the laser will frickin’ cut it exactly as you’ve drawn it. This is worthy of some type of award because it will save a lot of time for people. I constantly have students who would benefit from simply being able to draw their designs by hand and quickly cut a part out. Again, this feature somewhat comes from newer research into user interface design of laser cutters I’ve been keeping my eye on for some time now.

Paradigm shift 3: Glowforge uses dual cameras inside the cabinet to not only allow you to place your design on the material, but it can conform and auto focus even on non-level materials. The example on their web video mentions etching a design on a macbook, but this is sooo much more powerful and useful than just that. Many materials you want to laser, such as a 1/8″ piece of plywood, have a warp to them. If you focus your laser on the low part of the warp, then keep that measurement to cut the whole part, you can end up with edges that aren’t exactly as you had designed them, or edges that are weak due to the wood not ablating and instead burning. This is bad for a couple of reasons. One it can start small fires, but more commonly your edge is brittle and ashy. This changes the workable dimensions of your parts and sometimes makes them unusable.

Also, the cameras can detect materials you put in the machine. There are barcodes on the materials you buy from Glowforge, but you can make them yourself, which tell the machine what settings to use for engraving or cutting the material. Settings are different for plastics versus wood, etc. Even different densities of wood matter, so this is a great solution to the problem of figuring out what power and speed settings to set the laser to use.

And finally on this point, it seems there’s also some image recognition. Put your laptop in there and you it’ll detect it’s a macbook and know what settings to use to best etch it. It can even bring up possible designed others have submitted online for you to use if you want.

Paradigm shift 4: The firmware as well as a simplified version of the cloud software will be made open source. This is great because I can hack on it (as I would have done anyway, but at least now I have a much better starting point) . I’m certain a community of hackers/makers will be adding features, which is exciting since this machine is already starting with an impressive set of features.

Paradigm shift 4: On the Pro version of the machine, you can open the front and back to be able to cut material that is 20″wide, but infinitely long. This comes from two places, the vinyl cutting machines that are in the market (which can cut a certain width, but practically an infinite length of material from a spool), the Shaper and the awesome Shopbot Handibot (Shoutout to our friends and fellow Carolinian’s; thanks again for the help this past summer in Pittsburgh Salley!), which can do large designs piece-wise. The cameras on the Glowforge can help align the previously lasered portion with your design and make adjustments as needed. This is incredibly helpful for making sure the finished product comes out correctly.

Glowforge will also host a libray of other peoples’ designs you can choose from if you aren’t the artistic type. This is similar to Makerbot’s Thingiverse or Ultimaker’s YouMagine for 3D parts and Inventables’s project section for CNC projects and file, which can be imported into Easel (Inventables’s cloud-based CNC CAD/CAM software for their line of Shapeoko, Carvey, or X-carve machines).

Words of Negativity: For the specs of the machine, the 20″ wide cutting area is slightly awkward and a 24″ width seems more practical. Also, since the Glowforge isn’t out yet, I have to wait. I have to wait to see if it lives up to these expectations, and also wait to play with it myself.

All that being said, the Glowforge sale at this point is a presale. I won’t receive my machine until summer 2016 or later, but you have until the time it ships to cancel your order and get a full refund. I expect any bugs in the system will be worked out before I get mine and if not, then I’ll have a good excuse to play with it in more depth.

Disclaimer: The only affiliate link in this post is for the Glowforge. All other links supplied in this post are to simplify your internet browsing adventure.