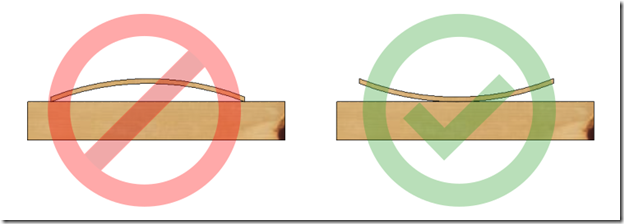

Holding a workpiece is always an annoyance. You want to flatten a sheet of plywood so there’s no part of it bowing upward because that will throw off your cut depths. Nothing is worse than thinking you have a tab holding a part in place only to find out that the tab was too thin or nonexistent when the interior piece starts getting all chewed up and flopping around, breaking stuff. On close inspection you can see that on your final couple of passes, the tab was cut too thin or clean through because the wood was bowed upwards. Without a vacuum table, there’s only so much you can do, but I’ve found a few ways that seems to work great. Screwing or clamping the wood to the spoilboard is OK, but it makes certain areas no-go zones for your bit. My methods will help you use up every square millimeter of the wood if you’d like.

Dealing with the Wood Itself:

The wood itself is always as straight as I could find, but it’s never perfect. I lay it on my machine such that the cupped edges stick up in the air. Then I mount down the edges. There shouldn’t be a bubble in the middle because the curve was originally downward to begin with and since I affix the edges (where all the stress to move upward is) it lays pretty well.

Traditional Method using screws:

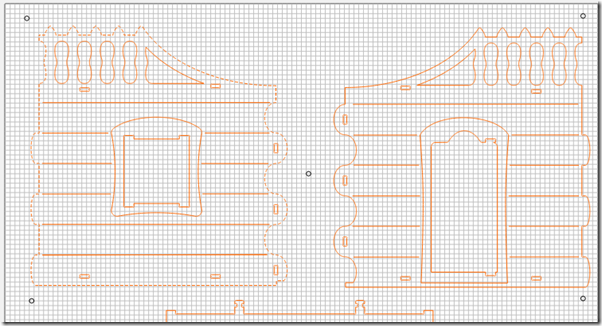

Sally from Shopbot showed me a nifty trick. If you do use screws to secure your stock to the machine you want to make sure your toolpaths will never touch the screws (lest you break your bit or mill your screw head off). Sally’s trick is to add these screw holes to your design.

- Lay your stock on the machine and center it but don’t mount it.

- Open your cutfile and add small circles (1/8th – 1/4th inch diameter) about 1/16th inch deep to the design. These are the locations of your screws. Make sure they won’t interfere with any cutpaths and that they will be in a good position to secure the stock.

- Export just these circles as a cut path and cut them.

- When finished, add screws in these locations (The black circles in the image below)

- Delete these added circles from the design

- Cut your design file as normal.

This method works great, however if the stock is bowed or there are small clearances in the cutpath of your design, or if you aren’t using tabs to support interior pieces this method might not work for you so try the other ones listed below.

Masking Tape and Cyanoacrylate (CA) Glue (Super Glue):

I stole idea this from a few places. Machining metal parts you can straight-up super glue them into place on your vice. Make sure the faces are clean of oil and debris first of course. When finished, you can simply dissolve the glue with a heat gun to remove your part.

The problem with wood is that if you superglue it, it can make it all nasty looking for the next few steps of the project. And what if you wanted a nice natural finish? The solution is to use masking tape. You’ll lay down a piece of wide masking tape to the spoilboard, then apply another to the stock material. Lay down a line of CA glue on the piece on the spoilboard and spray the piece on your stick with CA activator. As soon as you touch the two that piece is going to stay in place pretty well.

This method works best with smaller material that isn’t very tall. It also allows you to cut pieces on top of the tape without the need for tabs.

Masking Tape and Hot Glue:

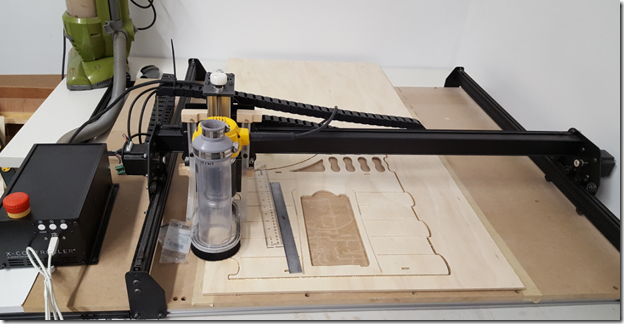

For larger pieces of stock I’ve found the use of wide masking tape and hot glue to hold large sheets fairly well. You might think hot glue isn’t a good choice, but I’ve used hot glue to hold down guitar body blanks on my large planing jig while I router-planed them to thickness without any issue. These were solid poplar about 1 and 3/4 inch thick. I simply use a high temp glue gun and a harder (rather than flexible) glue. I’ve also used it to mount 1/4” plywood on my CNC machine for tons of engravings and through cuts to great success.

On the CNC machine, I used masking tape to lay down on the spoilboard since I was doing a bunch of cuts. After a few pieces of plywood were cut the glue makes it hard to get a flat surface so you can just pull it up and put down new tape to glue to. The masking tape sticks to my spoilboard on my machine making an outline of where the wood will go with a bit of overlap so that the wood lays on top of about 1/2 the wide of the tape. Align the tape with the router head, not the machine itself. Move the router 10 inches at a time and make sure the middle of the tape is right under the bit. Here you can see the 1.5-2inch wide masking tape just under the wood:

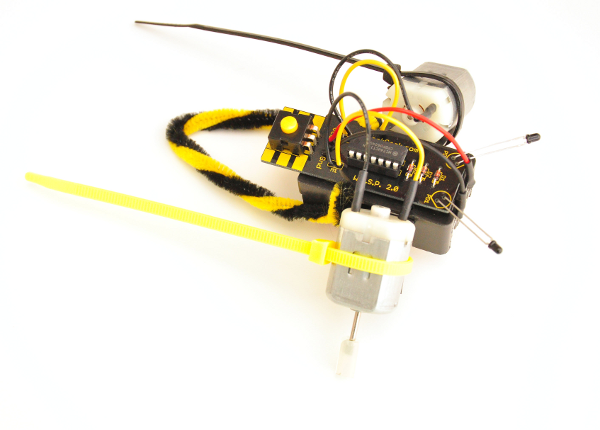

The Endmill (the Bit):

An additional tip for keeping the material flat is to always use Down Cut endmills or compression bits on pretty much all plywood cuts. These endmills have the spirals cut backwards such that the normal spinning of the bit puts pressure in a downward motion as opposed to upward. Compression bits actually have regular flutes on the top, but reverse flutes the rest of the way up to give a nice finish on the both sides of the cut. This isn’t a great thing to use for deep narrow pockets, but for plywood stuff it works very well for making sure the material doesn’t raise up when you are cutting.

Can you think of any other tips or tricks I haven’t listed here? Leave a comment and let me know about it!