So I was at the bin store the other day and I came across a couple of Baofeng TP-8Plus radios. I’m no expert on HAM radios in general (please correct me on anything I’m wrong about on this page BTW), but I got these two for $7 each so I couldn’t beat it. It turns out, the models I picked up are now a ubiquitous hardware model with different firmware which can be used for multiple purposes.

Firstly, I can’t tell the differences, but the TP-8Plus is apparently also called the UV-13 Pro.. as well as many other models (listed below). There are different levels when talking about radios like this, HAM and GMRS. HAM radio is amateur radio and you have to pass certifications tests for the license. These radios are classified as HAM radios since their broadcast power is too high for GMRS (which is a higher powered two-way walkie-talkie band). To use GMRS band, you need a radio rated for this band and a GMRS license (no certification test required) and your whole family can use the radios apparently. The radios are too powerful as they are for this, however there’s a firmware you can get for them that limits the broadcasting power turning them into GMRS-legal radios (from what I have read..)

Where to get Firmware:

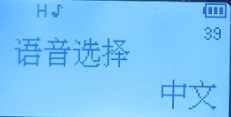

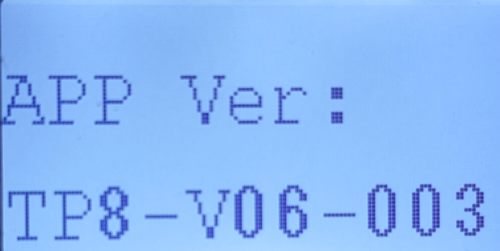

Before doing anything, I took a pic of the current firmware version as shown below. You can see this by holding the flashlight button as you turn on the radio

I was unable to figure out how to copy this ROM onto my PC, but I did find an older version of the UV-13 firmware I could use to replace it if I needed to… which I did. I wish I could find the firmware online.

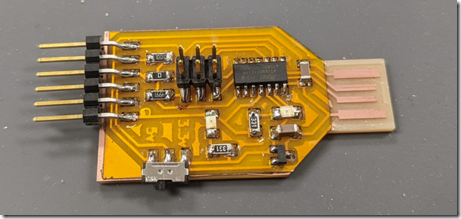

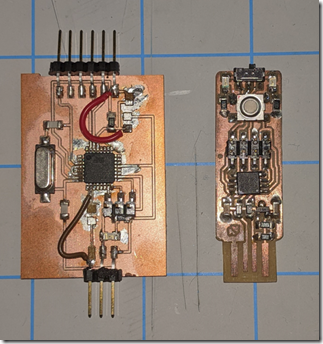

Where do you get firmware? It depends on what you want your radio to do. I have it on the authority of some random dude on reddit and other that this radio’s hardware “is the same for Baofeng UV-13, TP-8, Explorer QRZ-1, TYT TH-UV88, Pofung P15UV, Rugged GMR2, TIDRADIO TD-H5, Retevis RT85, and Radioddity MU-5, GM-30.” Firmware for those radios should work here. They each have slightly different abilities, so it is really up to you. what you’d like it to do. Do your research to see what legal licensing steps you can take based on how you want to use your radios. Comment below if you know where to find other firmware for this radio.

For using this as a HAM radio (where you can enter in frequencies manually or scan them in the 2m band) the UV-13 firmware was easiest to find. The only version I came across online from multiple sources was UV13-Firmware-V06.01.013-20211104_01013.bin I was able to successfully install this without issue and I can still write program settings using the P15-UV software.

For GMRS walkie-talkie usage, I came across the Radioddity page with their firmware. It is important to note that after installing this firmware, I had to use Radioddity’s own version of P15-UV branded “GM-30”. The link to their firmware and programming app is here. From what I read, this firmware limits the transmit frequency making it legal to use the radio. NOTE: I am not a lawyer and I have no way to test the radio’s power with this firmware to compare, it is just what I read on the internet.

Programming:

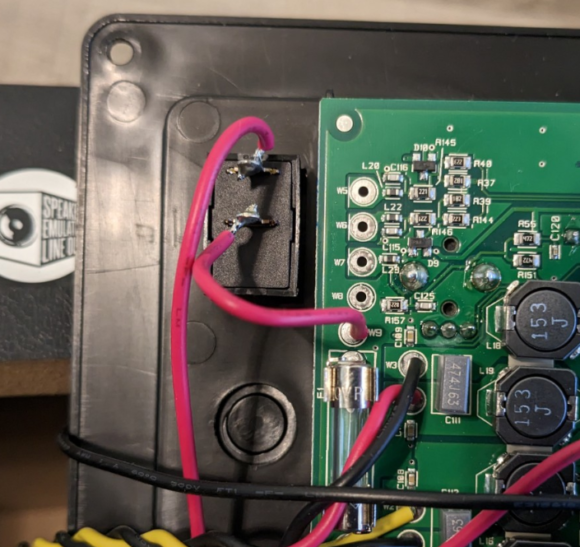

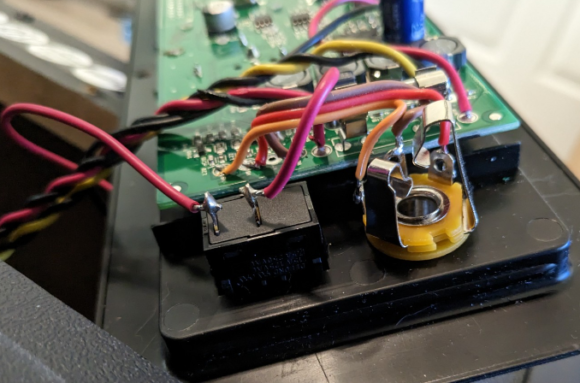

There are 2 programming modes. One for just reading/writing programmed channels and settings, and another mode for updating firmware. There’s a trick to program firmware I describe below.

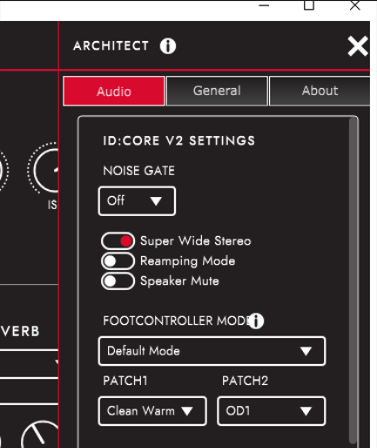

The software for the Baofeng firmware is P15-UV CPS software. I was able to find a version of it from a company called abbree. This only works for the Baofeng firmware. I had to get my copy from the wayback machine as the link on their main download page was broken. This is different software than my older UV-5R used. If you have the GM-30 firmware installed, you must use this Radioddity branded version of the programming software.

-

- I already had a USB cable for these radios since I had an older model. Once installed you can plug it up to the radio, turn on the radio and connect. In the PUV-15 software, select “Program–>Communication Port” and select the com port. If you don’t know which this is, open windows device manager and look for the COM port that disappears when you unplug the cable.

- Next you want to back up and save all the channels and settings from the radio by selecting “Program–>Read from Radio” and click “OK” to read all the default settings. Then you have to click “File–>Save As.” This will save your channels and any program settings to a file on your computer.

- To flash the firmware, download your preferred firmware version (more on this below) and select “Program–>Tool” For this to work you must manually put the radio in programming mode by turning it off, holding down the PTT and Flashlight button as you turn it back on again. You know you did this right when the screen does NOT come on, but the red light at the top glows dimly.

- Click “Upgrade” button on the app to change the firmware. DO NOT INTERRUPT THIS PROCESS or you might brick the device.

- Rewrite the channels and program settings by choosing “Program–>Write to Radio”

- If you were a genius like me and forgot to backup your settings, your menus and voice might now be Chinese. No problem, simply change the language by scrolling through the menu that says this:

Then pressing the menu button to edit and the down button to change it to English. Press menu again to confirm the change.

Licensing:

Again, I am no expert on the matter, but here’s what I learned from all the forum posts and videos I found on this radio. There is no license required to use these radios as listening-only devices. You can use them as weather radios or even emergency service scanners. If you wish to transmit at all you’ll need either a GMRS license or a HAM radio license depending on what firmware you have and how you plan to use the radio. See the comparison chart below:

GMRS HAM One license covers your family. Licensing process is confusing, so watch a recent tutorial video on the process to find out the steps required. One license covers you. You can allow your family to broadcast, but you must be there with them at the time. No exam required Must pass a certification exam (there are different levels) To be used as walkie-talkies (eg. in your family) because they are shorter-range transmissions. Connect with community of HAM radio operators all over the country, world, and even on the international space station! Use Radioddity GM-30 firmware and their custom programming app. Use Beofeng UV-13 firmware and the P15-UV programming app. License last 10 years License lasts 10 years Cost $35 Cost $35